Due

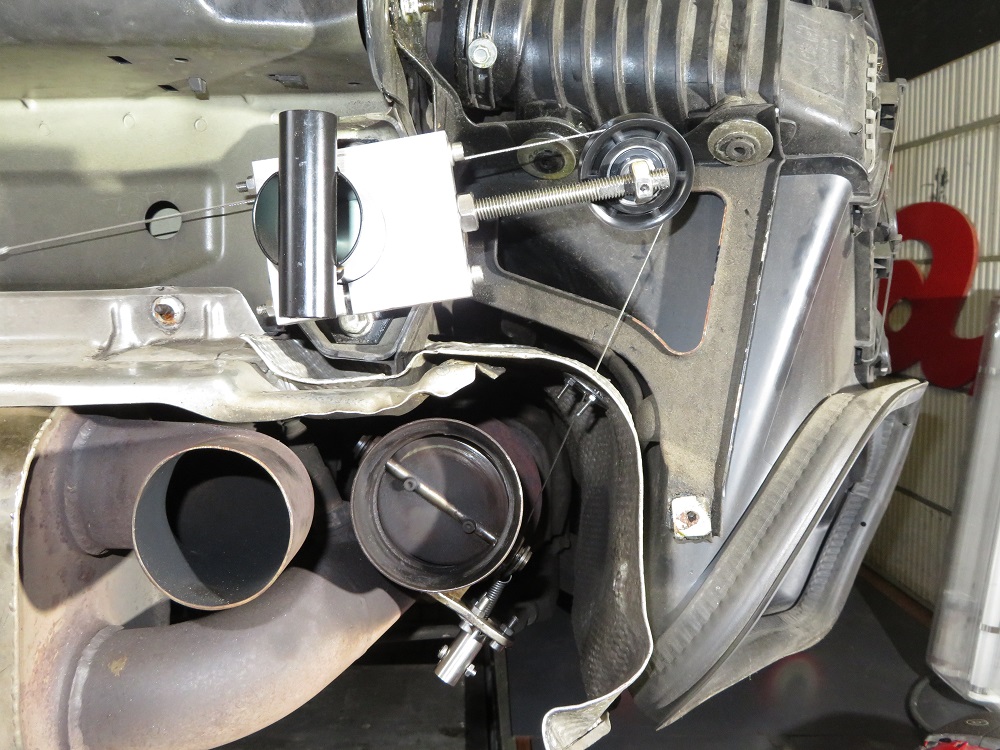

to a small crash a new 9FF exhaust including flaps was mounted on my

997 Turbo MT 2008. The old exhaust flaps were default closed but

unfortunately the new fitted exhaust had default open flaps. As

the flaps are controlled by a pneumatic actuator it took some time

before the under-pressure was low enough to close the flaps. So

directly after starting my flaps were open for some seconds which is

not acceptable in the neighbourhood I am living in. Furthermore the

pneumatic actuators were not very reliable.

So I decided to build my own flaps control system.

Requirements

- flaps electrically controlled

- heat resistant

- moisture resistant

- reliable

- bolt-on and avoiding drilling holes

- operated from drivers position

Design

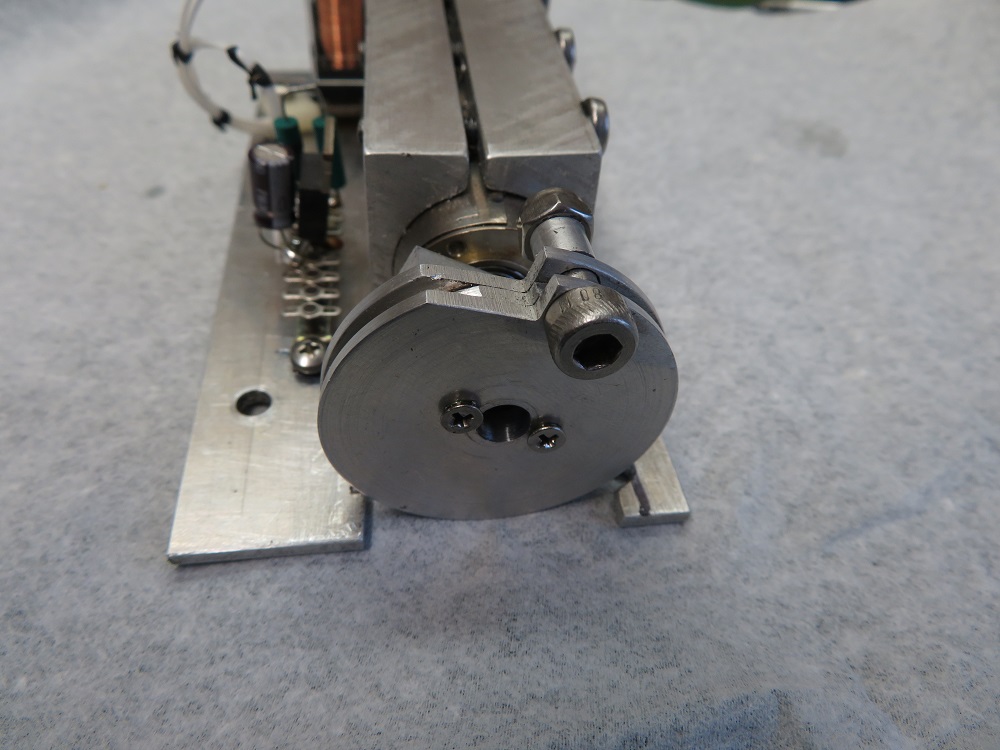

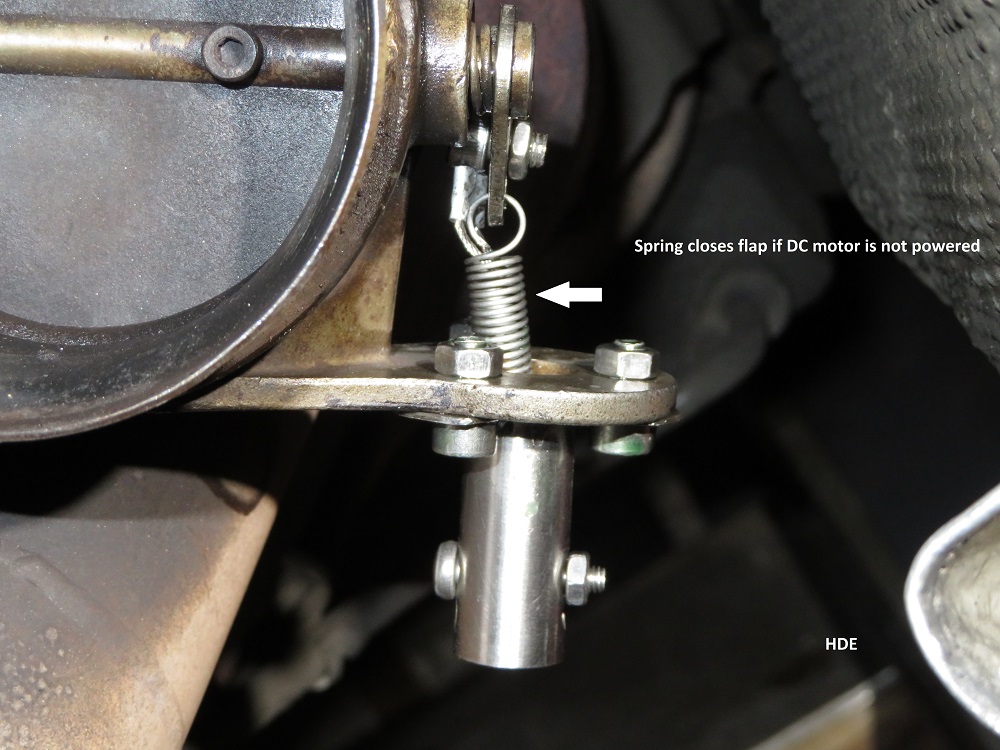

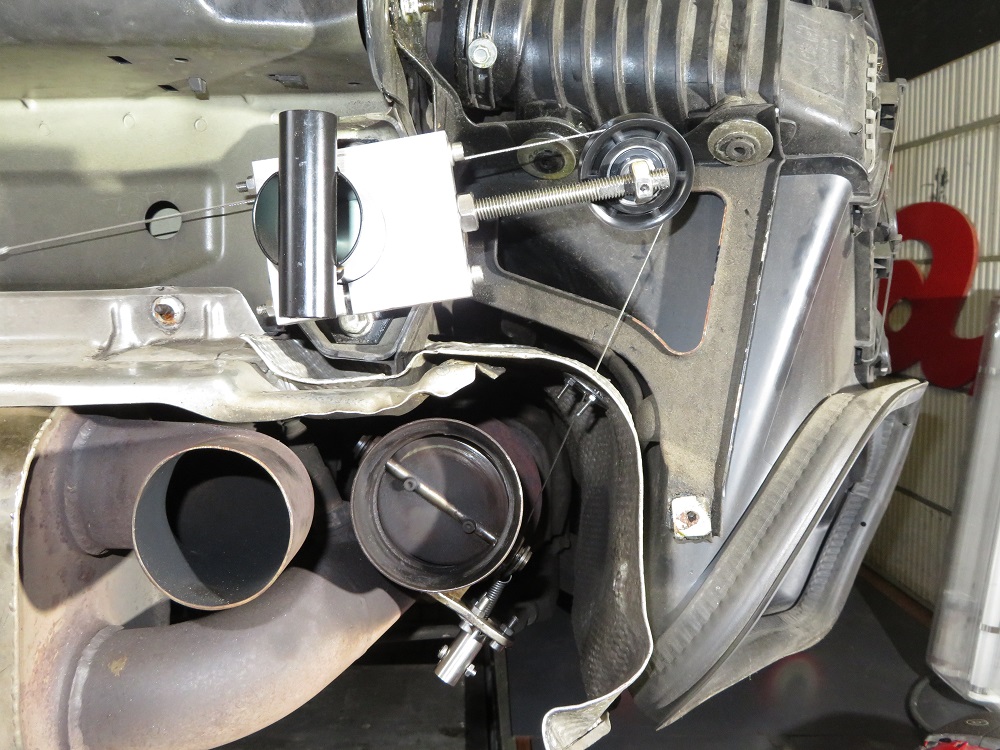

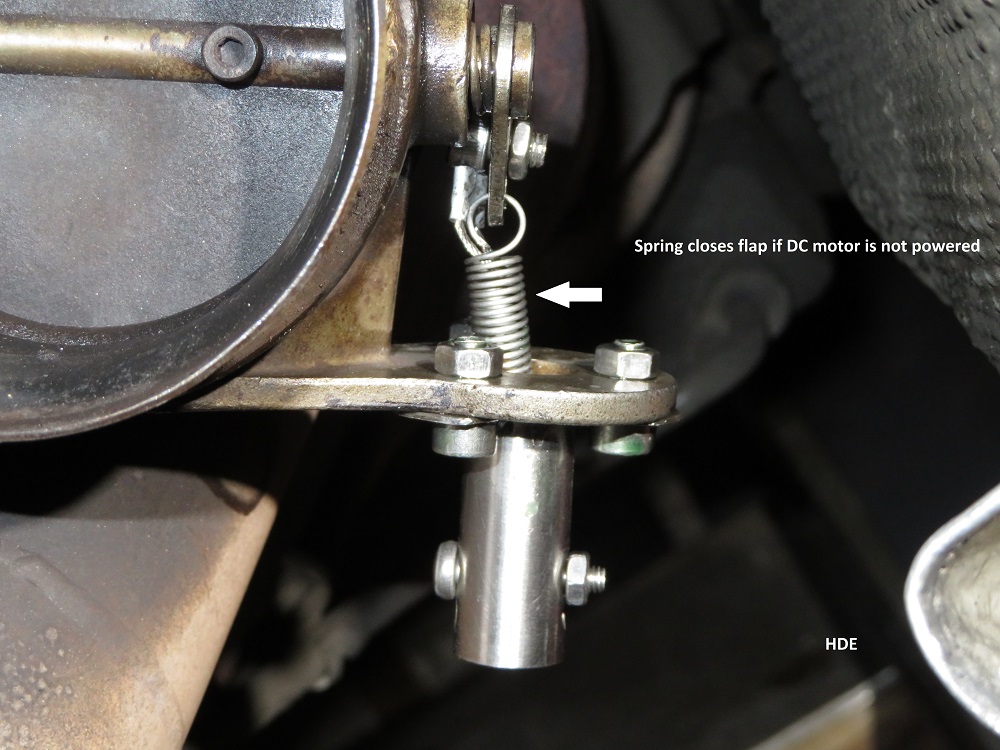

- flaps controlled by 1 mm stainless steel wire

- central winding-unwinding unit with DC Motor

Flap control

The flaps control consists of some Alu brackets, Cable pulleys and 1 mm steel wire

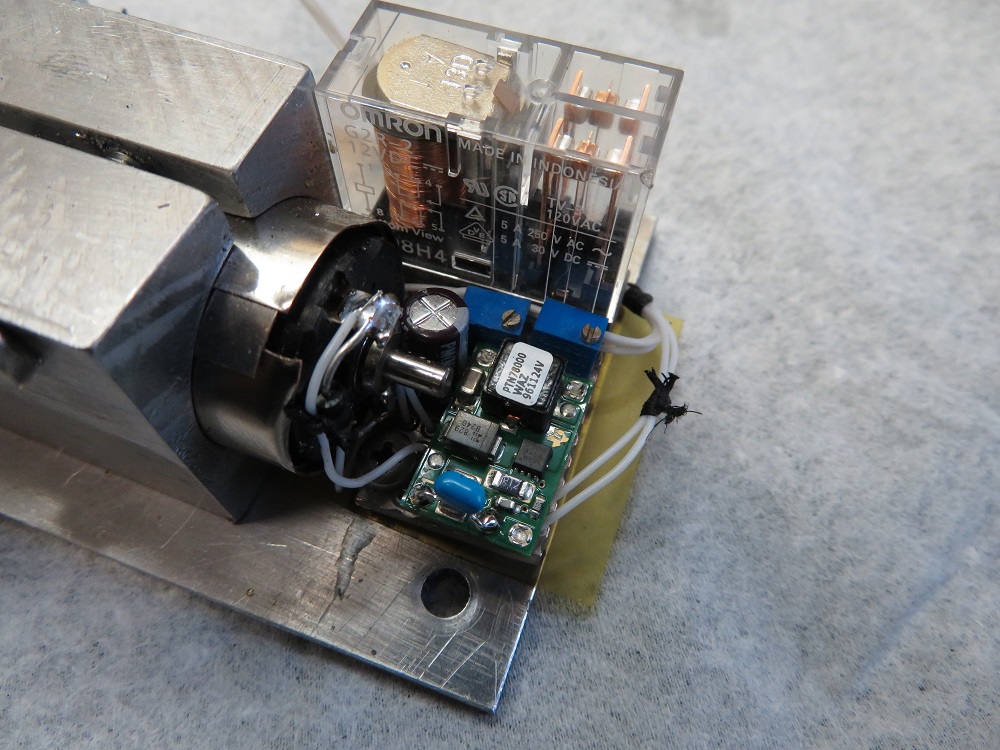

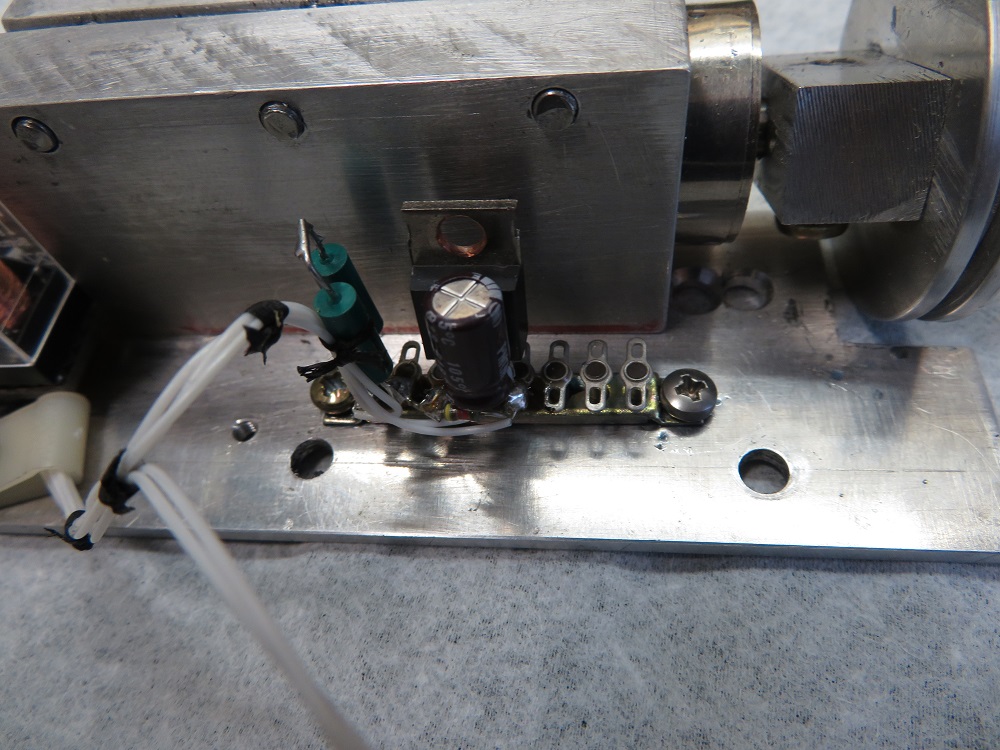

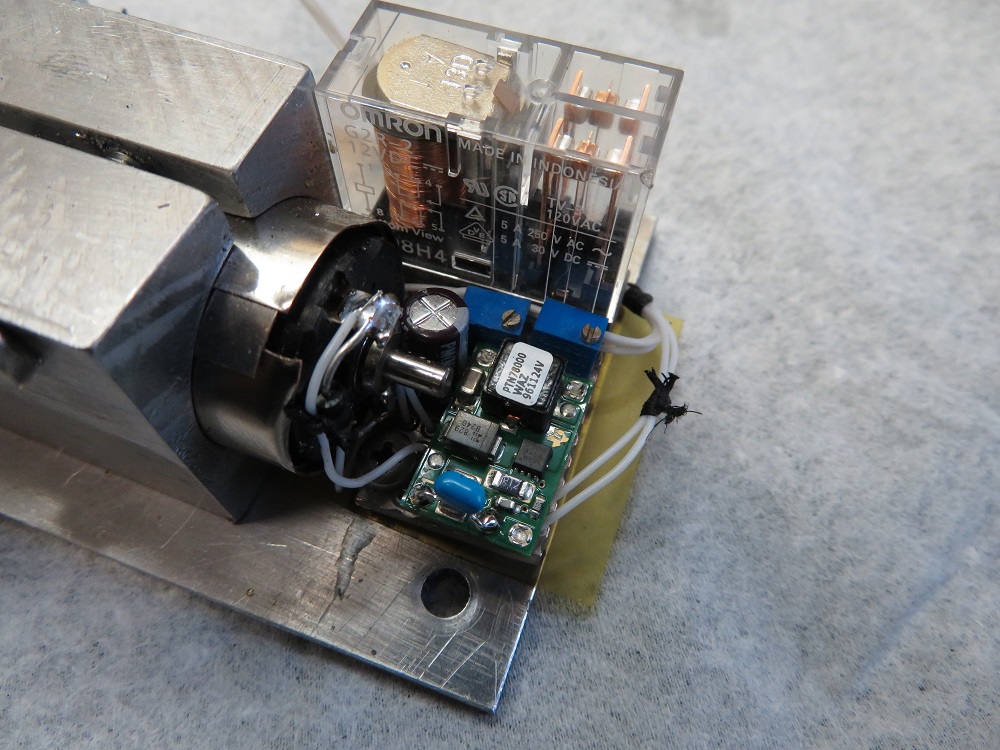

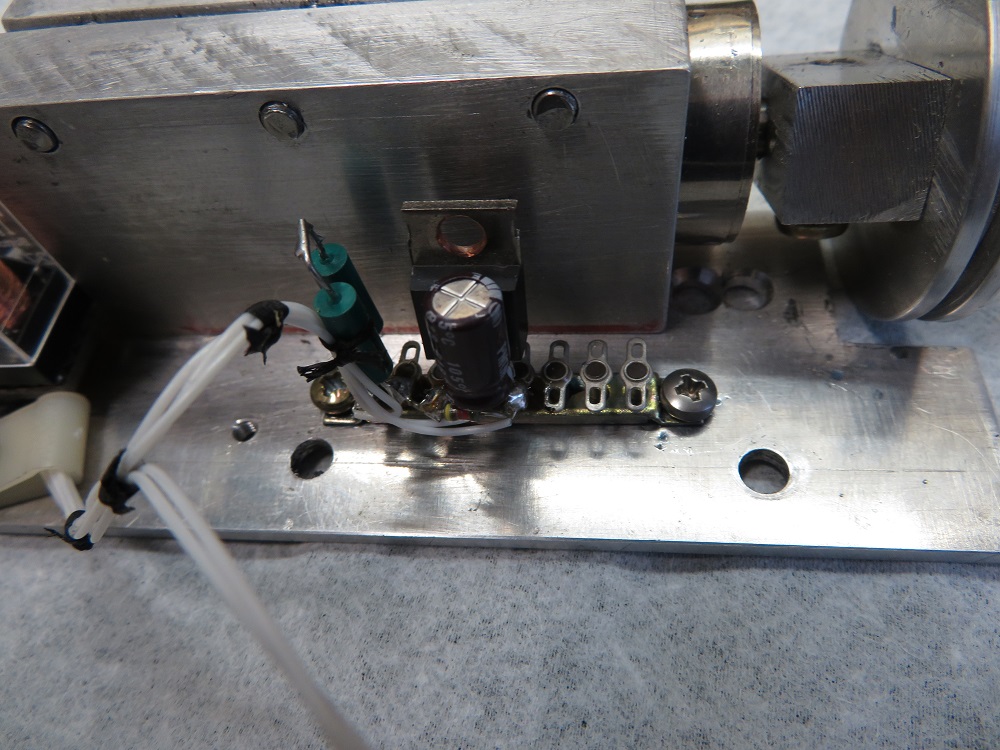

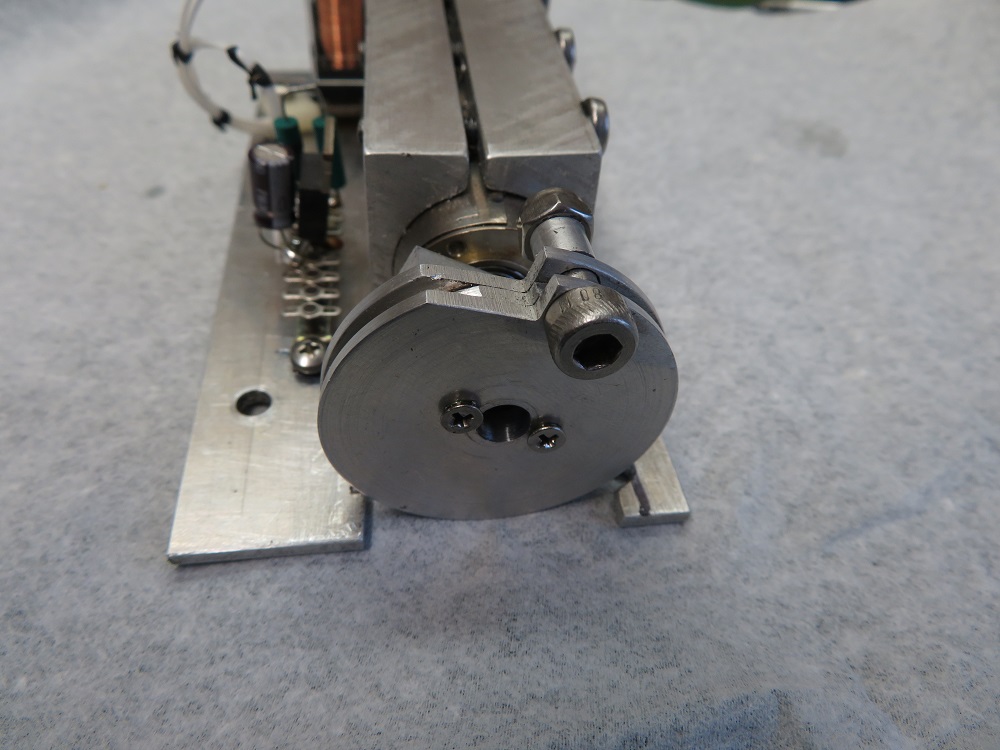

Central winding-unwinding unit

The unit consists of a 12 Volt DC motor with gearbox and some electronics.

The electronic part consists of a DC-DC convertor with switched voltage control.

During

the flap opening period the voltage applied to the motor is approx. 10

Volt. To avoid high motor dissipation 5 seconds after flaps opening, the motor voltage is

switched down to 4 Volt which is enough

to hold the flaps in the open-position.

To close the flaps the supply to the DC motor is switched off and the flaps close by springs located on the flaps

Prototype endurance test

The prototype was endurance tested for about 5 hours.

Endurance Test prototype